Data-driven management

In 2017, Rexel began a comprehensive transformation process designed to shift its business model from that of a pure logistics coordinator to that of a data-driven service company—a change that is in line with the new demands of the market, the competition, and the digitization of the economy. The Group has invested massively in this transformation in order to optimize the productivity of its operations and increase the added value of its services. Today, Rexel is a major digital leader at the forefront of its sector. Digitization represents a paradigm shift affecting every level of the organization, as well as all of its work methods and everyone’s mindset. Digital tools and data are now the company’s main assets, with a critical role to play in differentiating Rexel from its competitors and preserving its profitability.

Close

to 2/3

of the Group’s investments were made in information systems and digitization from 2017 to 2019.

Data richness

-

600,000 active customers, 500,000 online order-line per day, 50,000 client visits on the Group webshops, 15,000 quotes per hour: the analysis of the data to which the Group has access represents a source of information that the Group’s subsidiaries can adapt to suit the local context. The gathering and structuring of these data forms the foundation of a relevant, objective analysis of consumer buying behavior, in particular sensitivity to products, channels, means of interaction, price, and special offers.

-

“Most digital solutions developed by Rexel rely on increasingly sophisticated customer segmentation resulting from these data, completed by external data, and supported by validation algorithms”, explains Constance Grisoni, Data Solutions Manager. “This approach is intended to ensure objective segmentation.” In 2019 and 2020, the Group helped its various markets to improve data gathering and quality, harmonize products, and share best practices, with the intention to continue the effort in 2021.

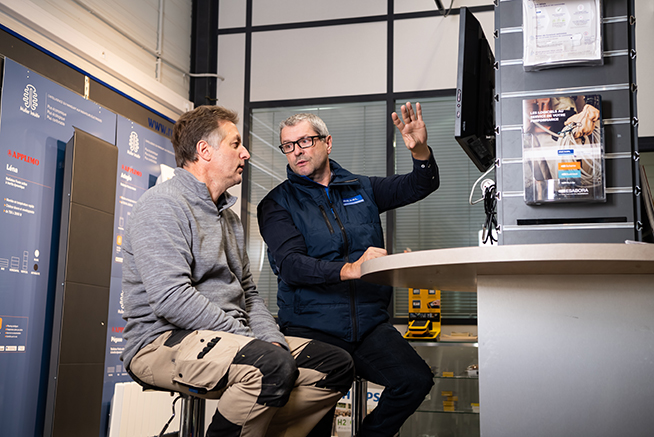

In the customer's shoes

“With a platform of 20 webshops and constantly rising digital penetration rates, the websites’ key advances today are in customer experience improvement”, says Nicolas Baltzer, Group Product Management & User Experience Lead.

Ergonomic tests, the first aspect of this improvement, have entered a phase of industrialization, at a rate of three to four times per quarter. The prototypes presented to customers before the launch of the new features and improvements ensure that their expectations and uses are fully taken into account in order to optimize the final customer experience.

Launched in 2019, they focus on customers’ priority projects: Track & Trace, product design pages (France), mobile payment at the branches (Sweden), etc.

In order to simplify and streamline digital uses from a customer experience rather than a functionality perspective, the premiumization trend is intensifying. It involves prioritizing technological choices that enable customers to work better and faster and is based on an observation of their behavior instead of on suppositions. This approach is used in priority areas set forth in Rexel’s Easy plan.

The Design System project aims for both visual consistency between different digital products within the same country and the provision of code components and reusable templates for local teams when they want to develop their own tools. Launched in late 2019, Design System is currently being used for various projects, including the customized landing page implemented in France.

Easy, with Rexel

Rexel Easy is a program launched in 2019 whose goal is to improve the customer experience by optimizing back office processes.

-

create an account in five minutes, online and offline

create an account in five minutes, online and offlineThe quick account creation mechanism led to a strong increase in new accounts.

-

look up delivery times

look up delivery timesNow available for all products, including those not in stock. In France, the various logistics systems have been integrated to enable the website to display a reliable delivery time for products not in stock.

-

track orders

track orders65% of customer orders in Europe are now covered by Track&Trace to monitor the status of online orders.

-

return a product online

return a product onlineAll the customer has to do is declare the reason for returning an order for it to be accepted by the sales teams. These streamlines and safeguards the process, while allowing the customer to do it independently.

-

Email to EDI

Signifying the automatic order processing of customer email orders, Email to EDI improves service quality as well as productivity. By the end of 2019, it was operational in six countries (France, Germany, Belgium, the United Kingdom, the Netherlands, Austria) and was implemented in Italy and Portugal in 2020.

66,488orders processed via Email to EDI in 2019.266,000lines of orders.

66,488orders processed via Email to EDI in 2019.266,000lines of orders.

AI boosts sales

-

“Over the past two years, we developed several artificial intelligence solutions aimed at accelerating the Group’s digital transformation”, says Constance Grisoni, Data Solutions Manager. “These predictive models are based on algorithms fed with high-quality data with the aim of optimizing sales. And they are a success.”

In order to reduce the customer attrition rate, or “churn,” a system of alert identifies at-risk customers so that sales people can react. This solution, which is in operation in several European countries including France, will continue to be rolled out as part of the end of the Covid crisis. Other tools were also created during the pandemic, such as rebound alerts, which identify customers whose business is recovering faster than average for their sector or who, on the contrary, are under-performing. -

“These alerts, which were implemented in many European countries and Canada during the first wave of the pandemic, have been preserved in order to give sales people a forecast of the evolving life-cycle of their customers”, notes Laurent Nizard, Data Science Manager.

In the branches, the mix optimization model aims to provide the right products at the right time in terms of product line breadth and depth. This solution was developed in a multi-disciplinary way between sales, procurement, marketing, and purchasing, with a considerable amount of training for inventory managers in the branches. Already in place in around 100 French branches, it is being extended to the entire country.

Rexel supports the creation

of a French AI research champion

-

On September 15, 2020, Rexel and four other major French companies announced Hi! Paris, an interdisciplinary center for research excellence in the fields of artificial intelligence and data analysis.

Led by two prestigious grandes écoles, Institut Polytechnique and HEC, Hi! Paris aims to become a French and European champion of science, technology, and business, capable of rivalling the world’s finest institutions. Its research on avant-garde projects will be the guarantee of improved competitivity for the companies that can implement it. -

The center is the result of a close partnership between the academic world and innovative companies involved in the digital revolution. Rexel thus joined forces with Total, L’Oréal, Capgemini, and Kering to create the project.

In so doing, the Group intends to maintain its technological lead and be recognized as a global reference in the use of AI for the energy industry. “The alliance between today’s industrial leaders and the top thinkers and researchers of the world of tomorrow is the key to our success in the coming years”, says Patrick Berard, CEO of Rexel.

Cyber security: three questions for Éric Laterrade, Group CIO

What form are the new cyber security requirements taking?

With close to 20% of our sales happening online, we must be extremely vigilant and exacting. Our cyber security program in place since 2019 aims to protect our users’ identity, our data, and our services. It takes three forms: training and raising employee awareness, risk management and assessment procedures in each market, and the implementation of tools for the detection of cyber-attacks and correction. We have a permanent team, which is in charge of running the network of security managers in the various markets.

What is the situation like today?

The program is almost entirely in effect in all of our markets. With strong support from Group leadership and investors equal to the task, it provides Rexel with the tools necessary to continue to fight against the significant increase in cyber-attacks observed around the world.

-

The Digital Factory

“The Digital Factory was created in 2018 to pool and provide markets and teams with methods and products designed to accelerate the Group’s digital development”, explains Anne-Brisce Grasset, Digital & Data Factory Director. The Group thus has a solid digital foundation to back up its business strategies in its various markets.

“The Digital Factory works in close collaboration with Rexel’s countries of operation to facilitate the adaptation of user interfaces and features to suit their markets and local specificities. The markets customize the solutions provided by the Digital Factory according to the regional strategic business directions and data that they have”, specifies Anne-Brisce Grasset.

This unit relies on global teams that provide the markets with common tools (webshops, apps, digital tools in the branches, etc.). They are high-quality solutions, personalized or personalizable, as well as tools and methods that facilitate their implementation and optimize costs. -

+10,000

automated tests were conducted for webshops updates.

Webshop updates

In 2019, the technical components of all of the webshops were updated in order to ensure the stability and longevity of the platform. The work was carried out from February to November 2019, in a totally transparent way for end customers, by mixed teams (Rexel-publisher) based in France, Poland, and India, thus demonstrating Rexel’s ability to bring its employees around the world together on a shared project.

“One of the project’s highlights, which is part of the general industrialization trend, was test automation”, explains Timothée Bertolero, IT Services Manager. “In total, more than 10,000 automated tests and around 2,700 manual tests were conducted. In accordance with this same trend, the e-commerce teams in the webshop program countries now have direct access to close to 100 articles with the use of the new tools available with this update.”